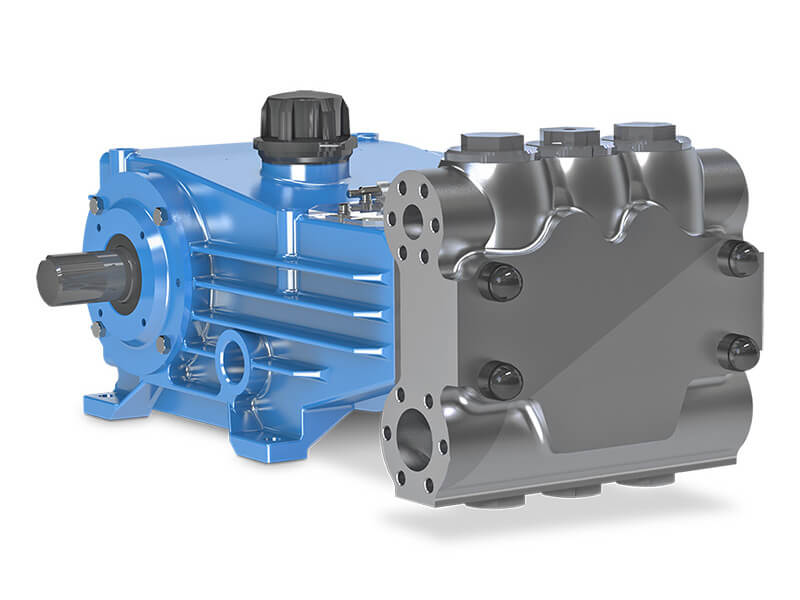

50 Series Plunger Pumps

The RAM50 Range of Triplex Reciprocating Plunger Pumps, are designed and manufactured to the highest degree of precision to ensure total reliability and efficiency.

Tailoring of the core design is easily performed with effective enhancements to metallurgy and elastomers in order to exceed the requirements of the process conditions.

As with all units within our range Ram Pumps are purposely designed and developed to maintain conformity to the latest quality standards and directives essential for supplying our tailored solutions to the most arduous and demanding applications.

50 HCH Series

Performance Table

Maximum Flow

| Bore | Stroke | Max RPM (API) |

Max RPM (Non-API) |

Max Flow (API) lpm/gpm |

Max Flow (Non-API) lpm/gpm |

|---|---|---|---|---|---|

| 55 | 65 | 420 | 600 | 185 / 48.8 | 264 / 69.8 |

| 50 | 65 | 420 | 600 | 153 / 40.4 | 218 / 57.7 |

| 45 | 65 | 420 | 600 | 124 / 32.7 | 177 / 46.7 |

| 40 | 65 | 420 | 600 | 98 / 28.8 | 140 / 36.9 |

| 35 | 65 | 420 | 600 | 75 / 19.8 | 107 / 28.3 |

Maximum Pressures*

| Material | BAR G | PSI |

|---|---|---|

| Carbon Steel WCB | 220 | 3,191 |

| Carbon Steel Gr 90 60 | 571 | 8,282 |

| 316 Stainless Steel | 200 | 2,900 |

| Duplex 22% Cr | 376 | 5,453 |

| Super Duplex 25% Cr | 402 | 5,831 |

| Inconel 625 | 418 | 6,063 |

*Maximum absorbed power rating for the Ram 50 HCH Series is 45 kW – Please ensure specific application data is calculated to determine maximum absorbed power required.

Key Features

- Flows of up to 264 litres/min or 69.8 gpm

- Maximum system pressures of up to 571 bar or 8,282 PSI

- Power of up to 45kw

- Speeds of up to 420 RPM

- Conforms to all the latest quality standards including ISO9001/2000, ATEX, Nace, EC P.E.D., Norsok, Gost and Stoomwezen

- Crankcase design with special built-in motor support mounting. Providing the option of installing the motor overhead to keep both the footprint and weight to a minimum.

- A range of liquid end materials are available including 316 stainless steel, 22% Duplex, 25% Super Duplex and Inconnel 625. Providing complete compatibility with pumping media.

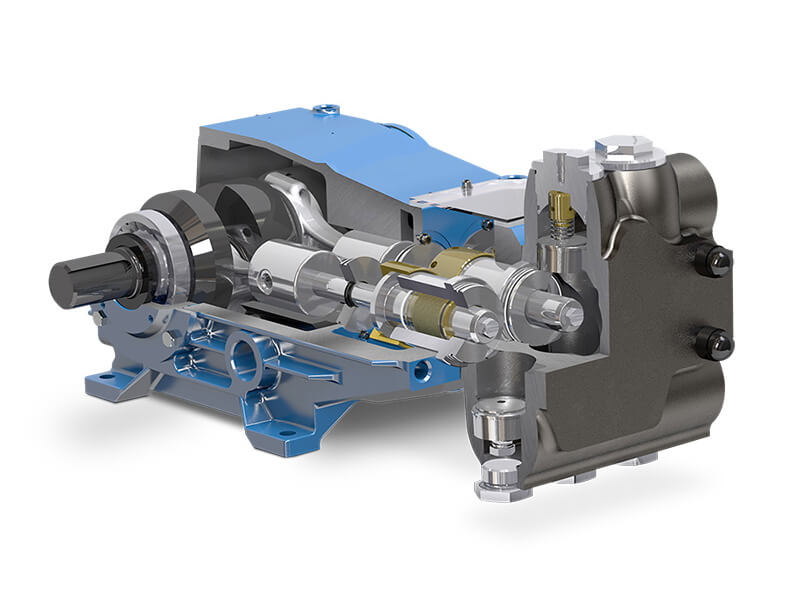

- Special pressure-formed, braided, PTFE impregnated Kevlar® packings. Offering exceptionally long life and a wide range of liquid compatibility.

- Packings housed in packing cylinder. Assuring proper alignment and optimum life.

- Plungers are specially surface treated for abrasion resistance. Solid ceramic plungers are also available. Providing the highest quality sealing surface for extended packing life.

- Spheroidal graphite iron crankcase. Offering exceptional strength, vibration dampening and flame and spark resistance for added protection in hazardous areas.

- Various plunger diameters available. Allowing for a wide range of performances to best suit the application.

- Standard splash crankcase lubrication with optional pressure lubrication system.

- Modular design.

- Customised builds available to suit individual clients specification.

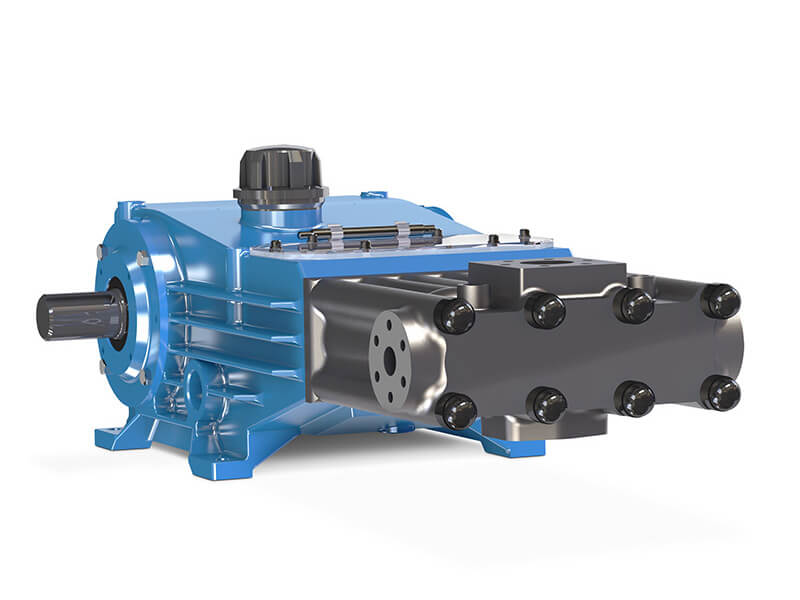

50 VHP Series

Performance Table

Maximum Flow

| Bore | Stroke | Max RPM (API) |

Max RPM (Non-API) |

Max Flow (API) lpm/gpm |

Max Flow (Non-API) lpm/gpm |

|---|---|---|---|---|---|

| 35 | 65 | 420 | 600 | 75 / 19.8 | 107 / 28.3 |

| 30 | 65 | 420 | 600 | 55 / 14.5 | 79 / 20.8 |

| 25 | 65 | 420 | 600 | 38 / 10.1 | 55 / 14.4 |

| 20 | 65 | 420 | 600 | 24 / 6.5 | 35 / 9.2 |

Maximum Pressures*

| Material | BAR G | PSI |

|---|---|---|

| ;Carbon Steel WCB | 560 | 8,166 |

| Carbon Steel Gr 90 60 | 1,599 | 23,191 |

| 316 Stainless Steel | 493 | 7,150 |

| Duplex 22% Cr | 947 | 13,735 |

| Super Duplex 25% Cr | 935 | 13,561 |

| Inconel 625 | 1,003 | 14,547 |

*Maximum absorbed power rating for the Ram 50 VHP Series is 45 kW – Please ensure specific application data is calculated to determine maximum absorbed power required.

Key Features

- Flows of up to 107 litres/min or 28.3 gpm

- Maximum system pressures of up to 1,599 bar or 23,191 PSI

- Power of up to 45kw

- Speeds of up to 420 RPM

- Conforms to all the latest quality standards including ISO9001/2000, ATEX, Nace, EC P.E.D., Norsok, Gost and Stoomwezen

- Crankcase design with special built-in motor support mounting. Providing the option of installing the motor overhead to keep both the footprint and weight to a minimum.

- A range of liquid end materials are available including 316 stainless steel, 22% Duplex, 25% Super Duplex and Inconnel 625. Providing complete compatibility with pumping media.

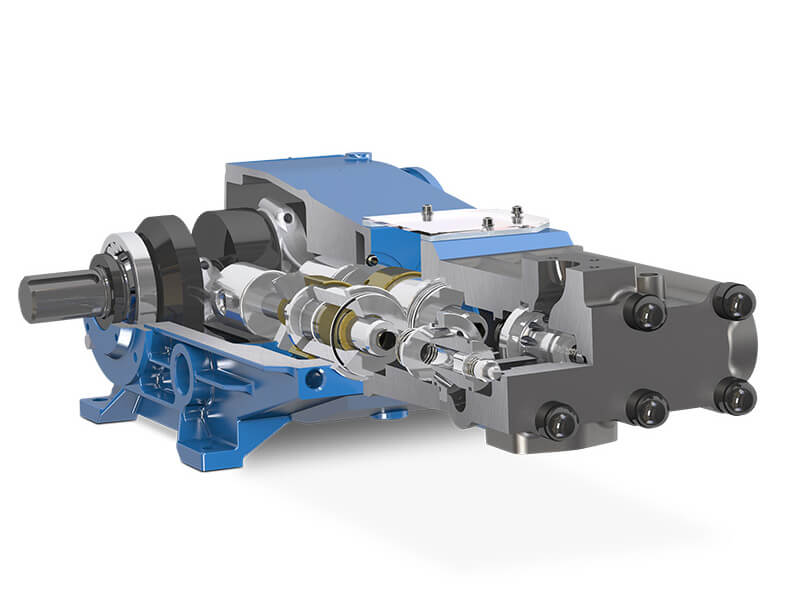

- Special pressure-formed, braided, PTFE impregnated Kevlar® packings. Offering exceptionally long life and a wide range of liquid compatibility.

- Packings housed in packing cylinder. Assuring proper alignment and optimum life.

- Plungers are specially surface treated for abrasion resistance. Solid ceramic plungers are also available. Providing the highest quality sealing surface for extended packing life.

- Spheroidal graphite iron crankcase. Offering exceptional strength, vibration dampening and flame and spark resistance for added protection in hazardous areas.

- Various plunger diameters available. Allowing for a wide range of performances to best suit the application.

- Standard splash crankcase lubrication with optional pressure lubrication system.

- Modular design.

- Customised builds available to suit individual clients specification.